24/7 Lift Maintenance Repair: Motivate and Reliable Solution

24/7 Lift Maintenance Repair: Motivate and Reliable Solution

Blog Article

Opening the Tricks to Effective Lift Fixes: Professional Insights Revealed

In the realm of lift fixing and upkeep, revealing the techniques that bring about efficient and effective service belongs to decoding an intricate challenge. Specialist understandings work as the guiding light through the labyrinth of difficulties dealt with by maintenance experts in the upright transportation industry. By diving into the depths of aggressive methods, fixing methods, and the continuous pursuit of ability enhancement, the path to boosting maintenance standards discloses itself. As we start this journey to debunk the tricks behind streamlined lift repairs, a globe of opportunities emerges, assuring a future where downtime is lessened, safety is focused on, and operational excellence comes to be the norm.

Usual Lift Repair Work Obstacles

An additional widespread difficulty in lift repair services is the absence of appropriate maintenance records. Without precise upkeep documents, repair service professionals might have a hard time to identify problems successfully or expect prospective problems. This can result in longer fixing times and raised expenses as service technicians function to fix issues without historic information to direct them.

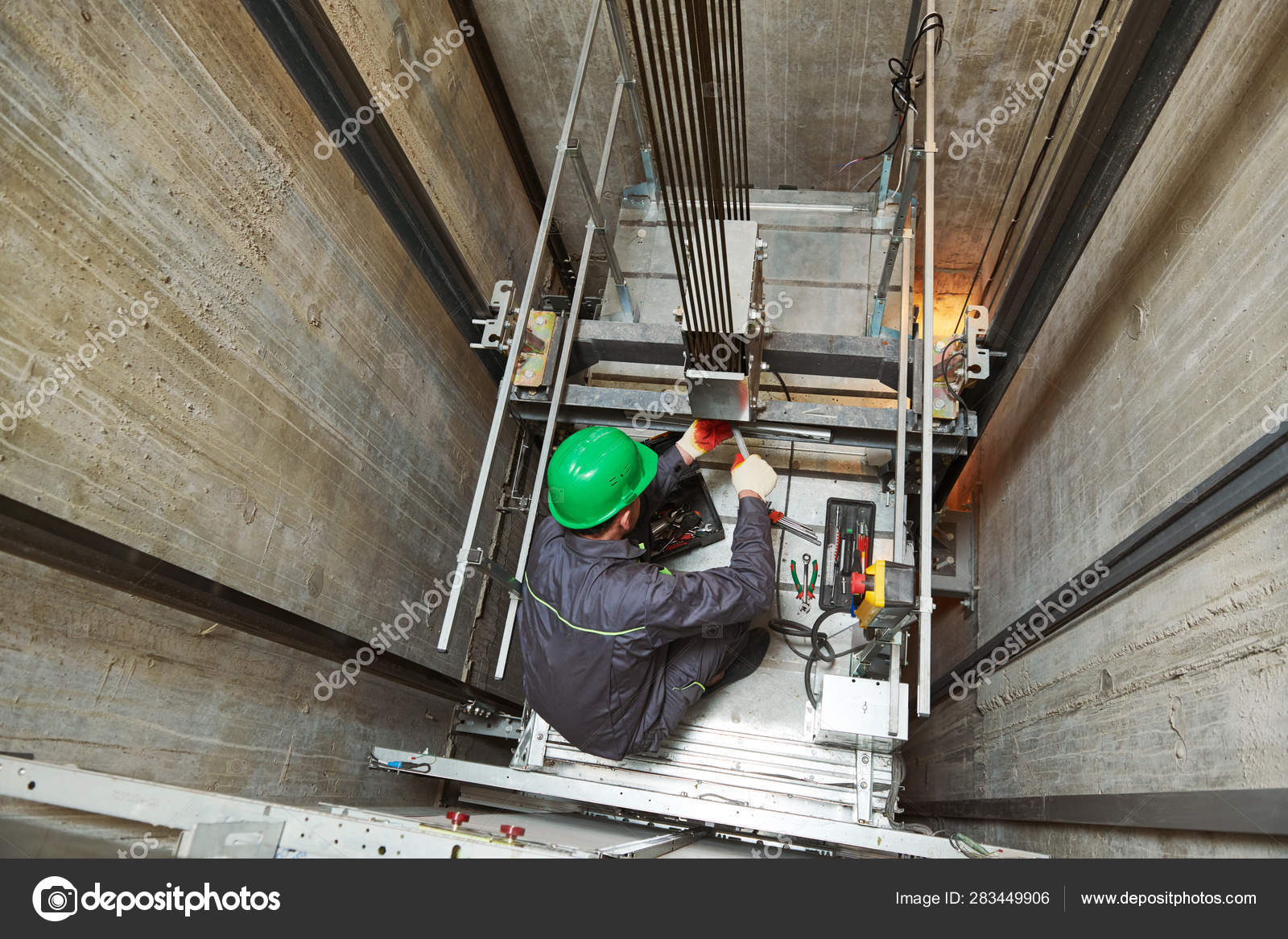

Additionally, access issues within lift shafts can pose substantial obstacles during repairs. Minimal area, awkward angles, and complicated equipment can make it difficult for technicians to get to the essential elements for repair job, extending the overall fixing process - Lift Maintenance Repair. By addressing these common difficulties proactively, lift repair service professionals can boost operational performance and guarantee the smooth performance of upright transport systems

Proactive Maintenance Methods

Executing aggressive maintenance methods is paramount for making certain the durability and optimum performance of lift systems. By taking on a proactive technique to upkeep, building supervisors and lift maintenance teams can resolve potential problems prior to they escalate right into costly repair services or downtime. One effective technique is to develop a normal maintenance routine that consists of thorough evaluations, lubrication of relocating components, and testing of safety functions.

In addition, buying training programs for maintenance staff can enhance their skills in determining prospective problems and doing precautionary upkeep jobs successfully - Lift Maintenance Repair. By encouraging upkeep groups with the expertise and devices required to proactively preserve lift systems, building owners can reduce interruptions, prolong the life expectancy of their lifts, and make sure a reliable and safe upright transportation experience for owners

Troubleshooting Techniques

Efficient repairing strategies are crucial for promptly recognizing and solving concerns with lift systems to decrease downtime and make certain optimum efficiency. When confronted with a lift breakdown, methodical troubleshooting is important to identify the source properly. One reliable method is to start with an extensive aesthetic evaluation of the lift components, examining for any type of noticeable indications of misalignment, damages, or wear. In addition, utilizing analysis tools and software can help in identifying digital or sensor-related issues that might not be right away apparent.

Enhancing Repair Abilities

Enhancing effectiveness in lift system repair services is a fundamental aspect of ensuring optimum capability and lessening operational disruptions. Lift service technicians should constantly work with sharpening their repair service skills to fulfill the demands of modern lift systems. One crucial approach for boosting repair service skills is normal training sessions that focus on both academic understanding and practical application. These sessions can cover a variety of topics such as brand-new innovations in the industry, repairing complex concerns, and safety methods. Additionally, professionals can gain from hands-on experience under the guidance of skilled professionals to boost their problem-solving capabilities and decision-making skills in real-time repair service scenarios.

Furthermore, staying updated with the most up to date innovations in lift technology is important for technicians wanting to enhance their repair service abilities. This entails proactively seeking information regarding new elements, software program updates, and upkeep strategies to effectively detect and fix concerns. By spending time and effort into continuous understanding and practical experience, lift specialists can significantly boost their repair work see this website competencies and add to the efficient performance of lift systems.

Raising Maintenance Specifications

Raising maintenance requirements in lift systems is vital for making sure long term functional performance and safety and security. Normal upkeep not just improves the performance of lift systems but also reduces the danger of unexpected malfunctions and makes sure the security of users. By adhering to rigorous upkeep protocols, lift proprietors and drivers can dramatically minimize the possibility of costly fixings and downtime.

Applying a detailed maintenance routine that consists of normal assessments, lubrication of moving components, and positive replacement of used elements is critical. Making use of sophisticated technologies like IoT sensing units and predictive upkeep software application can aid in checking the lift's condition in real-time, enabling prompt interventions prior to issues rise. Furthermore, giving constant training for upkeep personnel on the latest sector standards and ideal practices is crucial for maintaining upkeep excellence.

Moreover, fostering a culture of accountability and interest to detail amongst upkeep groups can even more boost maintenance requirements. Motivating open interaction networks for reporting and dealing with upkeep concerns quickly can aid in keeping a high level of lift system reliability. Eventually, by focusing on and boosting upkeep standards, lift systems can operate effectively and safely for a prolonged duration.

Final Thought

To conclude, reliable lift repairs require proactive maintenance approaches, troubleshooting techniques, and enhanced repair skills. By elevating and dealing with typical difficulties maintenance standards, maintenance specialists can properly make certain the smooth procedure of wikipedia reference lifts - Lift Maintenance Repair. Applying these specialist understandings can cause enhanced effectiveness, decreased downtime, and increased safety for both guests and tools

In the realm of lift repair work and maintenance, revealing the techniques that lead to effective and reliable solution is akin to understanding a complicated puzzle.An additional widespread difficulty in lift repairs is the absence of appropriate maintenance documents. By embracing a proactive Visit This Link strategy to maintenance, building supervisors and lift maintenance groups can deal with potential concerns before they rise into costly fixings or downtime.In verdict, efficient lift fixings need proactive maintenance strategies, fixing techniques, and boosted fixing skills. By elevating and attending to common difficulties upkeep standards, upkeep experts can properly guarantee the smooth procedure of lifts.

Report this page